Composite Materials:

- Made from two or more constituent materials

- Materials having significantly different physical or chemical properties

- Produced material has different characteristics from the individual components

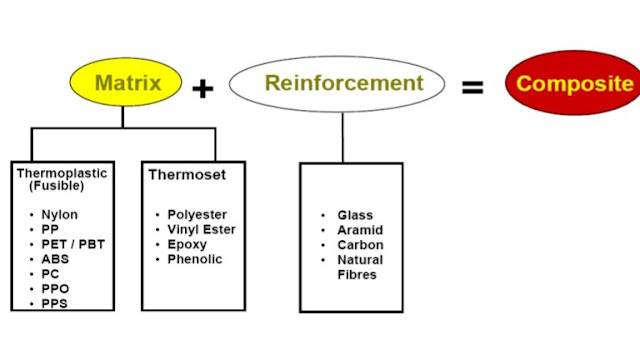

Classification Of Composites based on Matrices

What are Composites?

Why

Composites ?

- A composite is a mixture of two or more phases (materials)

- A better or unique combination of properties is realized when different materials (or phases) are combined

- The primary needs for all the advanced composites are:

- Light weight, higher operating temperatures, greater stiffness, higher reliability and affordability

What makes a material a Composite?

- Composite materials are formed by combining two or more materials that have quite different properties.

- The different materials work together to give the composite unique properties, but within a composite you can easily tell the different materials apart – they do not dissolve or blend into each other

- Composites can be produced using three classes of materials: Polymers, Metals & Ceramics ( Also natural composites are made from wood, bamboo,shells, bones, other tissues & Natural Fibres like cotton, jute, wool etc.)

Making

a Composite:

Most

composites are made up of just two materials. One material (the Matrix or

Binder) surrounds and binds together a cluster of fibres or fragments of a much

stronger material (the reinforcement)

Examples:

1) In case of

mud bricks, the two roles are taken by the mud and the straw; in concrete, by

the cement and the aggregate; in a piece of wood, by the cellulose and the

lignin.

2) In

fibreglass, the reinforcement is provided by the fine threads or fibres of

glass, often woven into a sort of cloth , and the matrix is a plastic.

Two phase

composite:

- Matric is the continuous phase and surrounds the reinforcements

- Reinforcement is the dispersed phase, which normally bears the majority of stress

What is Matrix in composite?

- Matrix is made from Metal, Polymer or Ceramic

- It is in Continuous phase

- Some ductility is desirable

- Binds the reinforcements (fibres/particulates) together

- Mechanically supporting the reinforcements

- Load transfer to the reinforcements

- Protect the reinforcements from surface damage due to abrasion or chemical attacks

- High bonding strength between fibre and matrix is important

What

is Reinforcements in composite?

- A reinforcement is the strong, stiff integral component which is incorporated into the matrix to achieve desired properties

- The term ‘reinforcement’ implies some property enhancement

- Different types of reinforcements:

- Fibres or filament: Continuous fibres, discontinuous fibres, whiskers

- Particulates reinforcement may be of any shape, ranging from irregular to spherical, plate- like or needle-like nanoparticles

- They have a low ductility

Polymer

A large

molecule (macro-molecule) composed of repeating structural units (monomer)

typically connected by covalent chemical bonds

Glass Fibre plays an Important role in Composites (in glass composites)

Polymer

Matrix Composite (PMC):

- Consisting of a Polymer (resin) Matrix and Fibre

- Very popular due to their low cost and simple fabrication

Applications of PMCs

Fibres

in PMCs

Various

forms:

- Discontinuous (chopped)

- Continuous or woven as a fabric

Fibre

used:

- Principal fibre materials in FRPs are Glass, Carbon & Kevlar 49.

- Less common fibres include Boron, SiC, Al2O3 and steel.;

- Glass is the most common fibre material in today’s FRPs; It’s use to reinforce plastics dates from around 1920

Polymer

Processing:

Forming

Processes for Thermosetting Matrix

Composites:

- Pultrusion

- ResinTransfer Molding

- Hand Layup and Spray up techniques

- Filament Winding

- Autoclave Molding

Forming

Processes for Thermoplastic Matrix

Composites:

- InjectionMolding

- DiaphragmForming

- Film stacking

- Thermoplastic tape laying

Post a Comment